Introduction

Hyperelastic Bone bioink is a biomaterial made by Dimension Inx composed of > 90% hydroxyapatite, the same mineral found in teeth and bones. This bioink is printed at room temperature, dries quickly, and can be easily seeded with cells post-print. Hyperelastic bone bioprinting can be used to print any number of orthopedic or dental constructs.

Hyperelastic Bone bioink offers several unique advantages over existing hard tissue biomaterials. It can be printed at speeds higher than 20mm/s, which is nearly a 10X increase over most bone materials. Despite being mostly mineral, it remains flexible, making it very user-friendly.

One of the biggest benefits of Hyperelastic Bone bioink is its ability to be customized. Drug molecules and growth factors can be easily integrated into the material before bioprinting.

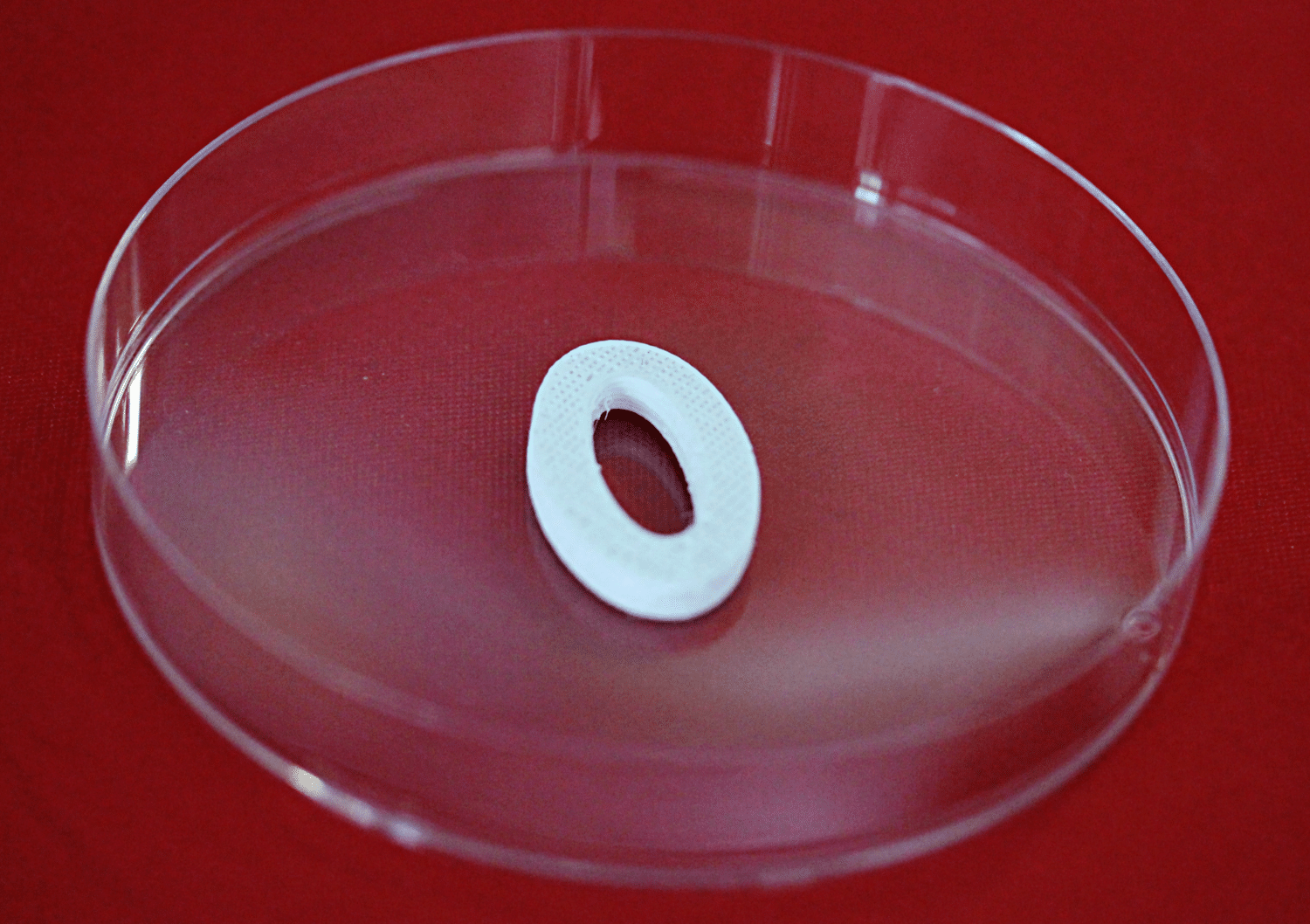

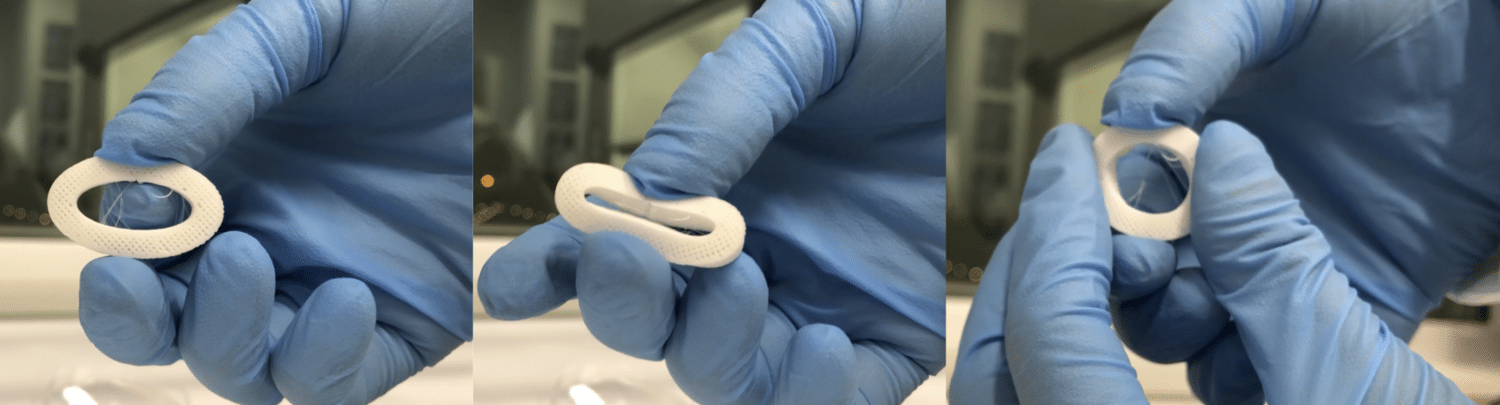

Hyperelastic Bone can be 3D bioprinted into user-defined structures and handled immediately. The 3D bioprinted materials and structures can then be cut, folded, rolled, punched, and further handled as the user the desires. Being comprised mostly of hydroxyapatite, this is an excellent material choice for hard tissue related modeling, basic science, and engineering research.

Materials and methods

Hyperelastic Bone Bioink is not currently commercially available.

Follow the Hyperelastic Bone™ Bioprinting Protocol to take bone modeling and engineering to the next level.

Troubleshooting

The printed construct is very elastic and might be too soft for bone implantation.

This is absolutely normal and by design. Its soft properties allow the construct to be easily manipulated—cut, rolled, folded, or sutured. This makes it easy to print and implant, but once in the body, it calcifies and hardens, changing its material properties.

It’s difficult to draw up Hyperelastic Bone into the needle.

Hyperelastic Bone needs vigorous vortexing before use. If you find it difficult to aspirate using a needle, increase vortexing time up to 1 hour. To speed up the process we recommend using a bioink mixer.

Hyperelastic Bone has dried up.

To salvage dried Hyperelastic bone, add dichloromethane dropwise and vortex vigorously in between. Continue adding until the material is at the desired consistency. To prevent it from drying, we recommend storing the material in an airtight glass container.

If your Hyperelastic Bone arrived dried up, please contact the Allevi Support Team at [email protected].

The needle clogs during Hyperelastic Bone printing.

This might be due to improper needle diameter. We recommend using needle gauge size G27 (0.2 mm inner diameter).

I would like to clean Hyperelastic Bone residues.

If you are printing with a reusable metal syringe or using a metal or glass surface, you can follow our thermoplastic cleaning protocol.

HyperElastic Bone doesn’t adhere to my printing surface.

If the HyperElastic Bone doesn’t adhere to your printing dish properly we recommend using Sandpaper Printing Surface. It will increase the friction between the deposited material and the surface to improve the quality of the first layer.

If you have any more questions regarding Hyperelastic Bone bioprinting, you can contact the Allevi Customer Success Team at [email protected].